purpose of notch in impact test|v notch impact test : store Positioning a notch precisely down the centre line of a single pass of a . webCódigo Promocional Solbet: *SOLPROMO*- recibe hasta S/750 de bienvenida. Desde ahora, registrándote en Solbet con el código promocional Solbet SOLPROMO, o ingresando al siguiente enlace, podrás acceder a .

{plog:ftitle_list}

Resultado da 5 de jun. de 2022 · A link to download R-User Games and yPER Studios’ free-to-play Spider-Man: Miles Morales Android can be found in the .

v notch impact test

The area beneath a stress/strain curve produced from a tensile test is a measure of the toughness of the test piece under slow loading conditions. However, in the context of an impact test we are looking at notch toughness, a measure of the metal's resistance to brittle or fast .Positioning a notch precisely down the centre line of a single pass of a .The Charpy V Notch (CVN) test is a basic method for defining toughness and, in this process, toughness is defined in “joules or ft lbs” at the “temperature of test”. There are other, more complex methods but the CVN test is cheap, is a good . For each type of impact test, a notch is cut into the test specimen, forcing the fracture of the specimen to occur at a repeatable location. Impact tests are performed so that engineers, manufacturers, scientists, and .

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This . Charpy impact testing, or V-notch testing, is an evaluation of a material’s strength and performance under impact conditions. It involves a pendulum with a pointed hammer on the end swinging and hitting a machined .

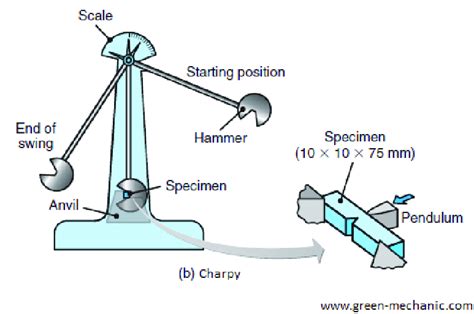

In a Charpy impact test to ISO 148-1, a notched metal specimen is severed using a pendulum hammer. For the test, the metal specimen is centered on the supports in the pendulum impact tester. The notch is exactly across from the . The purpose of the impact test is to assess the response of a known material, such as polymers, ceramics, and composites when subjected to sudden stress. It specifically evaluates the toughness, brittleness, notch .The notch. The specimen used in these kinds of tests have usually to be notched. The reason for notching the specimen is to provide a stress concentration area that promotes a brittle .A Charpy Impact Test involves striking a notched metal sample with a swinging pendulum. The amount of energy absorbed by the sample during fracture is then measured. This provides us with invaluable data about the material’s .

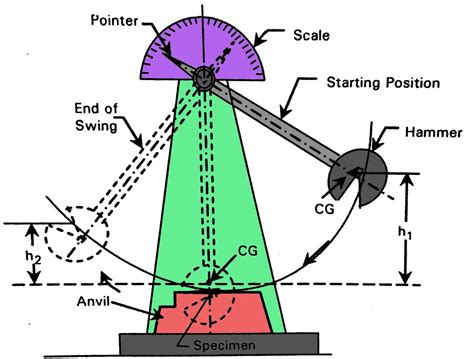

The value of energy absorbed is read directly from a dial on the machine. A typical impact testing machine is shown in Figure. 1. Figure 1. Schematic of a Typical Charpy Impact Testing Machine. In carrying out a test, the specimen . Key Standards for Sample Preparation and Impact Testing. ASTM E23: Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. Scope: This standard specifies the requirements for notched-bar . What is the purpose of V-notch in impact testing? The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the amount of energy absorbed by the specimen during fracture.

In a Charpy impact test to ISO 148-1, a notched metal specimen is severed using a pendulum hammer. For the test, the metal specimen is centered on the supports in the pendulum impact tester. The notch is exactly across from the point at which the pendulum hammer strikes the specimen. This impact test is used to determine the absorbed impact energy.The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen.

purpose of impact test. purpose of impact test. The purpose of impact testing is to measure an object's ability to resist high-rate loading. It is usually thought of in terms of two objects striking each other at high relative speeds. . Impact test specimen types include notch configurations such as V-Notch, U-Notch, Key-Hole Notch, as well .

Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.

What Is the Charpy Impact Test? The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy is required to fracture a pre-prepared and standardized sample with a V-notch machined into it. See Figure 1 below:

The impact engineers want to know when a material favours brittle fracture, some materials are ductile in a specific range of temperature, but they still fail like brittle material, why ? presence of stress risers, high rate of strain . , by bringing the notch they promote the condition of brittle fracture and the notch provides three .Understanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step-by-step Procedure of a Charpy Impact Test. Performing a Charpy impact test involves several important steps. How Charpy impact tests are performed. Specimen Preparation: A small, standardized specimen, usually a rectangular bar with a V-shaped notch machined on one side.The notch creates a stress concentration that promotes fracture when impacted. The test setup includes a pendulum hammer, a notched specimen holder, and a digital or analog .Izod impact tester in Blists Hill Victorian Town. The Izod impact strength test is an ASTM standard method of determining the impact resistance of materials. A pivoting arm is raised to a specific height (constant potential energy) and then released.The arm swings down hitting a notched sample, breaking the specimen. The energy absorbed by the sample is calculated .

The Izod impact test fixes one end of a notched specimen in a cantilever position by means of a vice. A striker on the arm of a pendulum or similar energy carrier then strikes the specimen. The energy absorbed by the specimen in the breaking process is known as the breaking energy. . The purpose of the notch is to serve as a stress .

u notch testing

IZOD test is vertical while Charpy tests are horizontal but both measure impact resistance. The main difference lies within a notch sample orientation during testing where in an Izod notched bar impact test, the specimen stands vertically with its notch facing towards the pendulum whereas, during charpy v-notch impact test ,the samples are placed horizontally . The purpose of this article is to provide an overview of the basics of impact testing. Our discussion will cover the different types of impact testing, the necessary equipment, and the valuable data these tests provide. Impact .

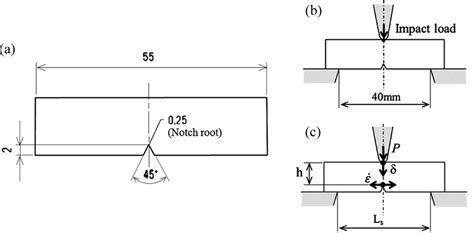

Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test. History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness of .The use of cylindrical notched specimens in impact testing was proposed by Philpot [S] in 1918. Although the cylindrical geom etry did not replace rectangular bars in impact testing, it did become popular for use in notched tension testing. The effect of notches on the tensile behavior of cylindrical steel specimens was described by Ludwik .The resulting test sample measures 80 x 10 x 4 mm. The depth under the notch of the specimen is 8mm. Data: ASTM impact energy is expressed in J/m or ft-lb/in. Impact strength is calculated by dividing impact energy in J (or ft-lb) by the thickness of the specimen. The test result is typically the average of 5 specimens.

The V-notch maker and impact test machine are displayed in Fig. 1.4 [8]. The impact strength is determined by the loss of energy of the pendulum as determined by precisely measuring the loss of height in the pendulum's swing [9]. Researchers also defined impact strength as the tendency of polymer composites to endure high-energy impact without . Procedure for Charpy Impact Test Specimen Preparation: Prepare a sample with dimensions of 55 mm x 10 mm x 10 mm, featuring a 2 mm notch at the center.. Test Specimen: Elevate the simple pendulum to its initial position and verify the correct adjustment of the testing machine.; Begin by calibrating the Charpy machine -rotate the dial gauge to the maximum . Purpose of the impact test The impact test is applied by requirement of standards (ASME, AWS, DIN, ISO, etc.) and we have several reasons to use it. One of the reasons is to evaluate the materials in equipment that will operate at low temperatures.

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . • U-notch or keyhole notch – A 5mm deep notch with 1mm radius at the base of the notch. What Does the Charpy Test Involve?The Izod impact test differs from the Charpy impact test in that the sample is in a cantilevered beam configuration instead of a three-point bending configuration. Notch toughness is a measure of the energy absorbed (impact energy) during the fracture of a specimen (in the presence of a flaw – usually a V-notch) of standard dimensions and .Notch impact test deice is in our day widely used and very common and such tests are conducted in accordance with current requirements. . The main purpose of the notch impact experiment is to artificially create a strain concentration that may eventually be present in the material (tension build-up) at the base of a notch during the impact to .

The purpose of fracture testing is to establish the resistance of a metal to fracture. In the impact tests, only the energy absorbed or the extent of cracking after a specified blow is determined. . The Charpy V-notch impact test is ASTM A370. The notch is located in the center of test sample. The test sample, supported horizontally at two .

karl fischer volumetric titration calculation discount store

681 votes, 101 comments. 481K subscribers in the CelebsBR community. As mais belas celebridades brasileiras. The Sexiest Brazilian celebs.

purpose of notch in impact test|v notch impact test